So, what drives dairy packaging?

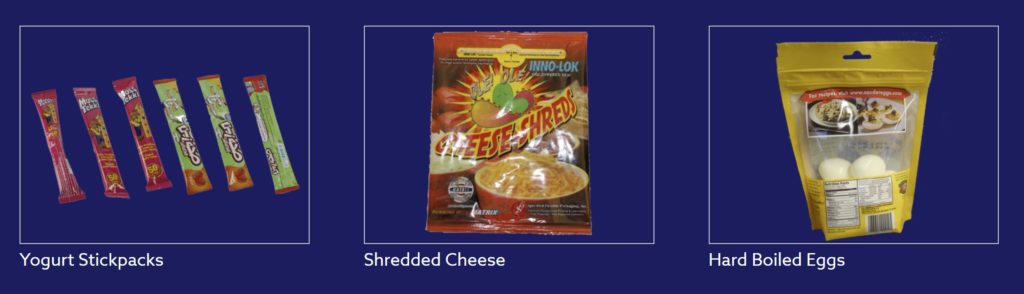

As we all know, packaging is in large part being driven by the consumer. They’ve made it known that they want products that are packaged conveniently. What this means will differ depending on consumer demographic, but in general will break into 3 main categories: bulk, family size, and single serving. Trends are showing that stand-up pouches, 4 sided sachets, and stand-out packaging designed with windows—for predominantly displaying the product, are what consumers are asking for. The use of re-closeable options like easy open, for example using flexible packaging to package sour cream in an easy squeeze, flexible package with a re-closable top versus a tub with a cover—making it simple and clean, and removing the need for a spoon. Tear notches and hanging options like a hole punch are also important as the consumer is looking for easy grab and go.

Are you asking yourself…How do I start making dairy packaging changes?

When you begin to consider making changes to your packaging, it’s important to review your company strategies and see which factors make sense with your current and forecasted plans. What are your marketing and branding goals? Are you asking your teams—how can WE distinguish ourselves from other similar products? Are you planning on focusing on branding, as well as functionality? Are your consumers big on single serve options? Other factors to consider are overall company strategies, for example, do you have sustainable initiatives? Do you want to reduce materials used, or offer recycling or compostable options? Now, the last question…will your packaging be profitable? Some of the largest challenges facing dairy processors is the ability to manage costs so that they can provide a profitable product. The raw product, processing the product, machinery, film, and workers, etc., all have cost. And processors need to be able to package their products in such a way as to still be profitable while keeping up with the challenge of consumers needs and wants.

Some of the new options, such as sustainable or recyclable films, stand-up pouch styles or flat bottom or gusseted packaging options can be more expensive, and some may require changing how the product comes down the line. Planning for these strategies in advance can give the processor time to get up to speed with new film choices, training operators and updating or purchasing new equipment.

Matrix Dual Morpheus Packaging Frozen Cheese Curds – Dairy Packaging

I have my dairy packaging concept, now what?

It’s time to talk to your packaging machine supplier. Working together is a must if you want to make sure your new packaging style of film has the correct structure and will seal correctly on the packaging machine. Talking with your suppliers to discuss new updates and available options will help you understand which ones make sense for your product.

Overall, determining effective packaging is going to include discussions with your supplier team. Will your product be displayed on shelves, hooks or pegs, bins, or other ways? Do you need an easy open option, a re-closable option, or both? Knowing the answers to these questions will help you and your team determine how to, not only effectively package your product, but also give you the ability to do it efficiently.

How can Matrix Packaging help me with my dairy packaging efforts?

We offer a variety of machines that can be used to help processors effectively package their products. Matrix machines can run a variety of films, including poly, resistance, netting, craft paper, compostable as well as recyclable and more. Hole punch and re-closeable options are also easily integrated and available. So, in the end you need to manage these options while also producing your product profitably.

The bottom line is to make a product that you can make a reasonable profit on—as that’s the only way to stay in business. Meeting these challenges are easier when your supplier teams work as true partners. When working together as a team, you can determine all the pieces that make up your dairy packaging as a whole and produce a packaged product that stays in-tune with what the consumer needs and wants and what you can feasibly achieve.

Subscribe to our email list for the latest in flexible packaging news.

Matrix provides flexible packaging machinery solutions to customers worldwide. Vertical form, fill, seal; horizontal form, fill, seal; pre-made pouches; stickpacks and sachets, Matrix can help you find your flexible packaging solution.