Welcome to the Matrix How-To Series, where we provide you with clear and concise instructions to troubleshoot and maintain your Matrix MVC-300 VFFS packaging machinery. In this post, we’ll guide you through the process of setting up film pull belts on the MVC-300 machine, a critical step to ensure smooth and efficient operation.

Understanding the Film Pull Belt Setup

Correctly positioning the film pull belts is essential for optimal performance. The belts, powered by a vacuum system, must be set accurately to avoid issues such as film misalignment or excessive friction. Follow these steps to properly set your film pull belts.

Step-by-Step Guide to Setting Film Pull Belts

- Turn Off the Vacuum System:

- Locate the pressure gauge. You should see a reading of negative 60.

- Turn off the vacuum by twisting the dial until there is no vacuum pressure on the left pull belt.

- Repeat the process for the right pull belt.

- Open the Film Pull Belts:

- Navigate to the film pull tab on your control panel.

- Use the “Open Full” button to open the pull belts.

- Position the Right Pull Belt:

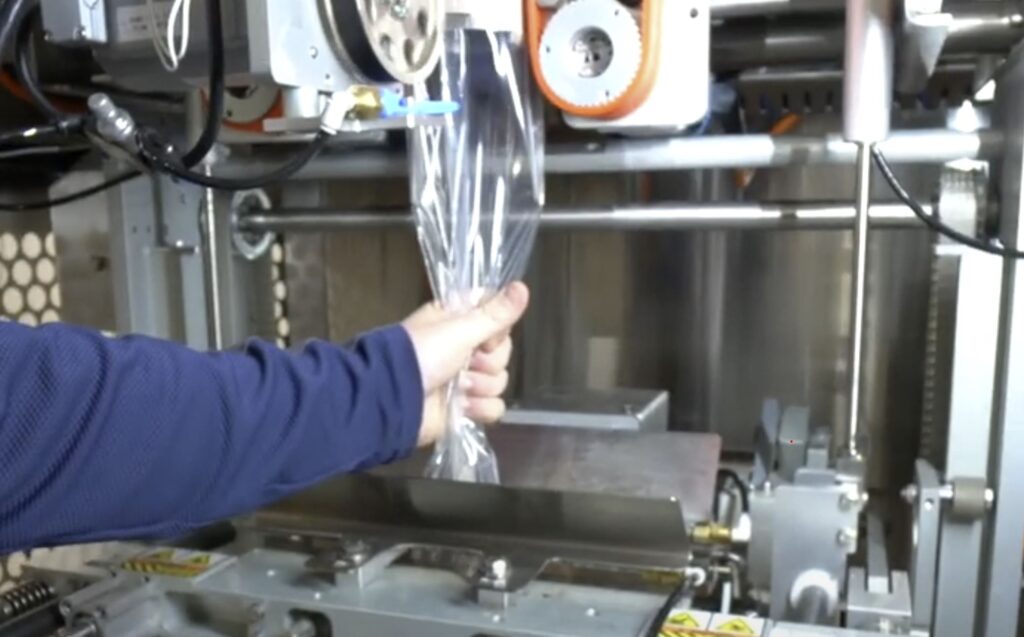

- Start with the right pull belt. Jog it in to close, stopping just before it touches the film.

- Test the tension by pulling the film downward. If it moves without resistance, the belt is too loose.

- Incrementally inch the pull belt forward until you feel back pressure when pulling the film down.

- Fine-Tune the Right Pull Belt:

- Adjust until pulling the film down encounters resistance, but sliding it left and right loosens it slightly.

- The ideal gap is small enough to fit a credit card between the pull belt and the forming tube.

- Repeat for the Left Pull Belt:

- Follow the same steps to position the left pull belt.

- Ensure that the film moves with slight resistance when pulled down, and loosens when moved sideways.

- Save the Belt Position:

- Once you have the correct position, save it in the machine’s recipe settings.

- Note the position value displayed (e.g., 1.56) and save this as the correct setting for future reference.

- Restore Vacuum Pressure:

- Turn the vacuum system back on, adjusting the pressure back to negative 60.

- Ensure both sides are set correctly.

Troubleshooting Tips

- Uneven Tension: Ensure both belts are evenly adjusted to prevent film misalignment.

- Excessive Friction: If there’s too much friction, the belts may be too tight. Adjust slightly until the ideal tension is achieved.

- Regular Checks: Include pull belt tension checks in your regular maintenance schedule to avoid unexpected downtime.

Conclusion

Setting the film pull belts correctly on your MVC-300 (Morpheus) VFFS machine is vital for maintaining efficient packaging operations. By following these steps, you can ensure your belts are properly set up, reducing the risk of film issues and enhancing overall machine performance. For more detailed maintenance guides and troubleshooting tips, stay tuned to the Matrix How-To Series.

If you have any questions or need further assistance, our support team is here to help. Ensuring your machinery operates smoothly is our top priority.

Subscribe to our email list for the latest in flexible packaging news.