By Brandon Day

The second a meat product is produced, the clock starts ticking to get it packaged, shipped, sold, and consumed. Completing all these functions in a short window of time requires impressive coordination all along the supply chain, and any boost to preserving freshness is a welcome innovation. Often, these product-preserving changes come in at the packaging phase, where freshness can be locked in and the expiration date extended.

Creating the Right Environment

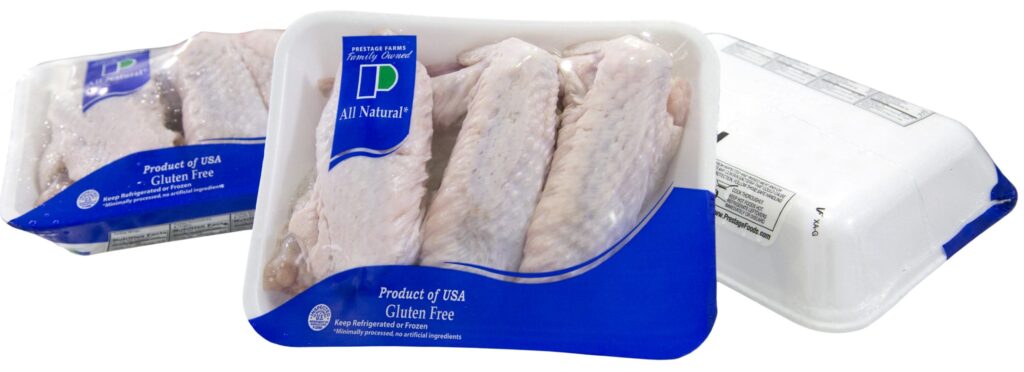

Tray overwrapping is one of the most common packaging styles for meat products, and for good reasons. A good seal with this method completely protects meat products from outside contaminants and prevent juices inside from leaking and creating a mess. However, packaging manufacturers can go a step further to completely maximize longevity.

Modified atmosphere packaging (MAP) is a subset of tray packaging that replaces the air inside the package with a more favorable gas mixture. This ensures that the package is not only protected from external factors, but internal ones as well. Utilizing a barrier film as an additional layer of protection can also increase shelf life and decrease wasted products.

Good Looks and Long Lives

Recipe kits and ready-to-eat meals are a growing trend across grocery retailers and packaging them comes with a unique set of challenges. Product presentation is even more important for these items than others, as customers typically make fewer modifications before they eat the meal. Companies producing ready-to-eat meals often work with chefs to design a product layout that presents the most appetizing image to the customer.

Packagers in this industry must preserve the integrity of the product design while also preserving the freshness of the product. Vacuum skin packaging has proven to be an effective solution. This style of packaging collapses film around the specific shape of the product, removing all the air and locking each piece into place. Customers can still see the delicious arrangement of ingredients, and shelf life is secure.

Operational Efficiency

The conversations around the impact of shelf life often focus on the retailers, but the product purveyors are just as beholden to the expiration date. Each item needs to have a reasonable freshness window by the time it leaves the facility. When the packaging does little to preserve that window, purveyors are forced to rush through packaging incoming products and changeover the line more often to manage all the inventory. A better package provides more flexibility, reducing the need for disruptive changeovers and growing the bottom line.

Subscribe to our email list for the latest in flexible packaging news.

Ossid provides superior tray overwrapping, flow wrapping, weigh price labeling, case scales, and horizontal thermoform fill & seal machinery. We are committed to designing and building solutions that protect product quality and fully meet our customers’ production needs.