What are some best practices to ensure peak food safety?

As a food packaging equipment manufacturer, we consider food safety to be a top priority for all equipment we have in the industry. Food sold at retail stores, as well as, to foodservice providers must be packaged in a clean, sanitary, and safe environment. Ossid equipment is designed to package products with the highest level of standards in the industry, including many IP65 wash down rated machines. Most of our equipment is self-operating after set-up, reducing the opportunity for contamination to occur at the packaging level. In addition, preventative maintenance scheduling built into our machines also reduces the risk of issues to occur within the packaging stage. Well designed and operating equipment is a must when it comes to food safety.

What are some best practices to ensure a long product shelf life?

Food shelf life varies drastically by the type of food being packaged, the shipping conditions, the retail environment and finally, the end user environment. To ensure food has a long shelf life, many forms of packaging must be considered in order to find the best solution for a particular product. Some items require high barrier films and reduced oxygen in the package to prolong shelf life, while other products require breathable film in order to maintain product freshness, such as dairy.

Ossid equipment can run a wide variety of films including breathable produce or poultry films, lidding films for gas flushing, to vacuum skinning films in which oxygen is removed from the package. As an equipment manufacturer, we stay up to speed on a wide variety of industry materials best suited for each product need.

Has any of your packaging or best practice methods changed due to COVID-19?

Our packaging formats have not changed as far as what we can provide customers with, but we have seen an increase in ready meal type of applications. We believe this is because consumers are looking for easier, safer options for to-go type of meals and less interaction with others, if possible. Another area we are seeing change is the fresh produce department. There are concerns with shoppers touching vegetables and fruit and thus we have seen an increase in overwrap produce packaging. This provides a layer of film protection between the consumer and the product, while still providing great product visibility, as well as the option for retailers to sell a bundle of product.

Fresh Produce on the Ossid High Speed Stretch Overwrapper 500Si

Best practices have certainly changed in regards to the spacing of plant workers, the need to wear mask and checking temperatures. Typically, food processors practice very good hygiene with frequent hand washing and wearing gloves, although this may be monitored more closely now.

Do you have any new packaging materials/technologies out this year?

We have been working with several suppliers on new sustainable packaging material options to run on our existing equipment. Over the past year we have seen a significant rise in recyclable or compostable materials, and these new materials are not always compatible with existing equipment and can take numerous testing cycles to perfect the materials. We work diligently with our material suppliers to ensure that our equipment has the capability to run these new materials, so that our customers can be the first to market with them. Our patented technology on several machines also allows us to run less film than competitors, enabling a huge savings to the customer.

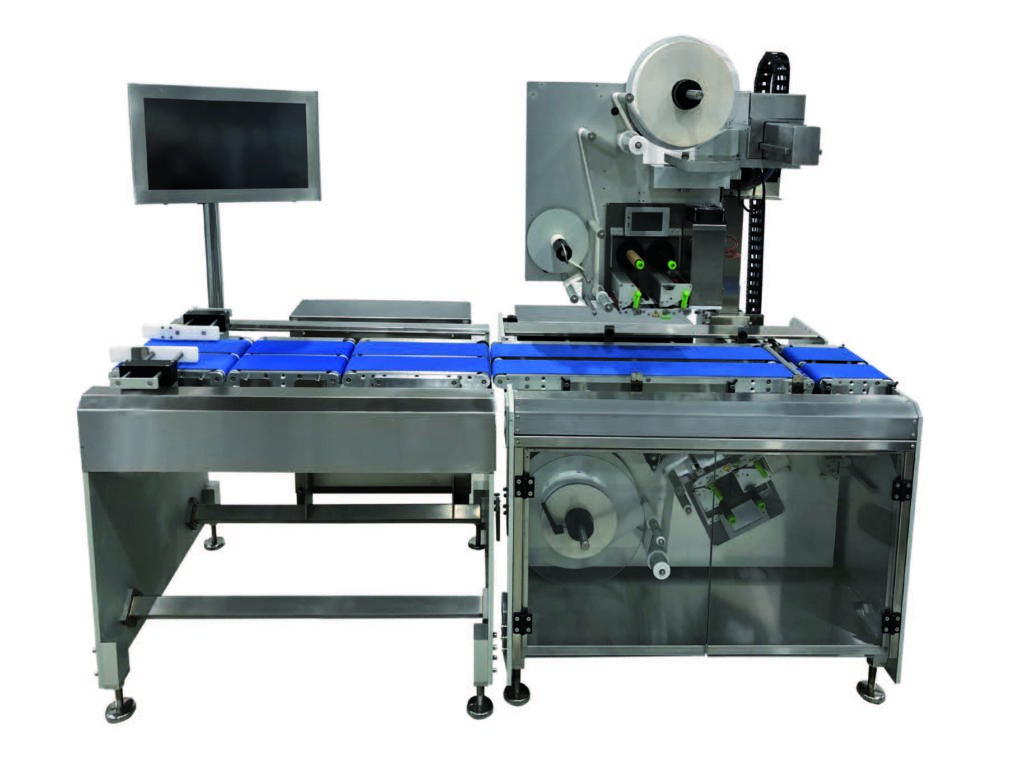

We’ve recently launched a new NextGen Weigh Price Labeler (WPL) machine that’s taken the market by storm. Our brand new weigh price labeler is used across almost all food industries, including fresh poultry, proteins, seafood, produce, cheese, and more! The use case for a weigh price label stands to ensure accurate product information and in many cases, includes important packing and/or product expiration dates.

Subscribe to our email list for the latest in flexible packaging news.

Ossid provides superior tray overwrapping, flow wrapping, weigh price labeling, case scales, and horizontal thermoform fill & seal machinery. We are committed to designing and building solutions that protect product quality and fully meet our customers’ production needs.