In the realm of packaging, versatility and adaptability are paramount. Thermoforming, a widely used process in packaging production, offers businesses the flexibility to create customized solutions tailored to their specific product requirements. Let’s delve into the intricacies of thermoforming and discover how it can revolutionize your packaging strategy.

Understanding Thermoforming

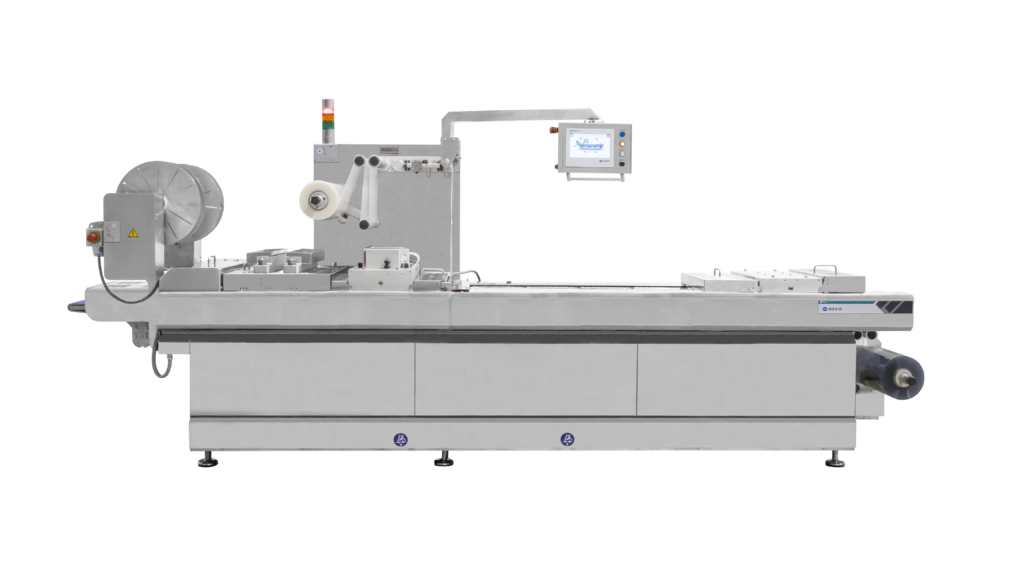

Thermoforming is a process that involves heating a film to form a pocket to securely hold the product. This pocket is then sealed to another layer of film, effectively enclosing the product within. Thermoformed packages can undergo various sealing methods such as vacuum sealing, vacuum skinning, or gas flushing (MAP), depending on the desired outcome and product characteristics.

Package Benefits

- Customizability: Thermoformed packages are easily customizable to suit the unique needs of different products, allowing businesses to create tailored packaging solutions that enhance product presentation and protection.

- Printing and Branding Options: With a wide variety of printing and branding options available, thermoformed packages offer ample opportunities for businesses to showcase their brand identity and product information effectively.

- Smaller Package Footprint: Thermoformed packages provide a smaller footprint at retail compared to rigid trays, optimizing shelf space and enhancing product visibility.

- Cost-Effectiveness: Thermoformed packaging can cost up to 15% less than other packaging formats, making it a cost-effective solution for businesses seeking to streamline packaging processes without compromising quality.

Customer Benefits

- Freezer Ready: Thermoformed packages are freezer-ready, offering convenience and flexibility for consumers who wish to store products for extended periods without sacrificing quality.

- Leak-Proof: Thermoformed packages provide reliable leak-proof seals, minimizing the risk of spills and contamination during storage and transportation.

- Space-Saving Design: Thermoformed packages take up less space, making them ideal for storage and transportation, while also reducing environmental impact.

- Easy Open and Resealable Options: Some thermoformed packages feature easy-open and resealable options, enhancing consumer convenience and product usability.

Material Options

Thermoforming offers a wide range of material options to suit diverse packaging needs, including:

- Flexible Films

- Semi-Rigid Films

- Foil

- Paperboard

- Vacuum Skin Pack (VSP), and more

Thermoforming emerges as a versatile and cost-effective packaging solution that empowers businesses to meet the evolving demands of the market. With its customizable design, extensive material options, and consumer-friendly features, thermoformed packaging stands as a cornerstone of modern packaging innovation. Embrace thermoforming to elevate your packaging strategy, enhance product visibility, and drive consumer engagement in today’s competitive landscape.

Subscribe to our email list for the latest in flexible packaging news.