Precision and Versatility: Ossid’s Medical Form Fill Seal Machines in Focus

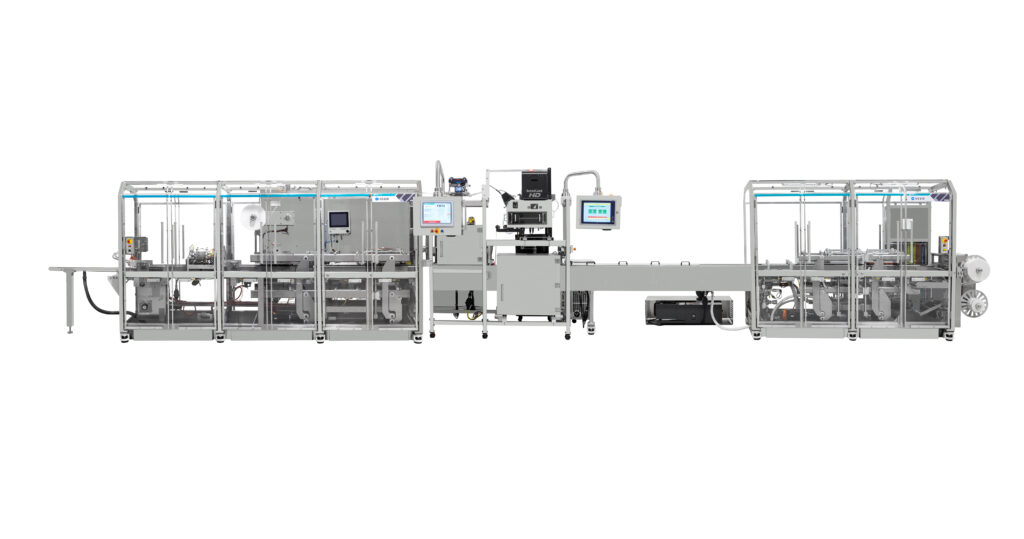

In the fast-paced and critical world of medical device manufacturing, precision, efficiency, and safety are paramount. Ossid, the leading manufacturer of high-speed packaging and labeling equipment, has established itself as a trusted partner in the medical device industry by providing innovative and customized packaging solutions. With their advanced medical horizontal thermoform fill seal machines, Ossid delivers precise and dependable packaging systems designed to meet the unique requirements of the medical industry.

Customization for Optimal Performance

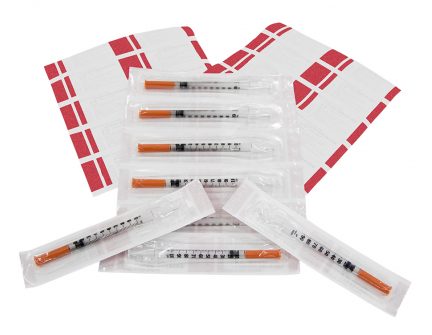

One of Ossid’s standout features is the ability to customize their medical horizontal form fill seal machines to each customer’s product needs. Whether it’s syringes, needles, dental kits, or emergency room equipment, Ossid’s machines are versatile and adaptable to accommodate various specifications. By offering tailor-made solutions, Ossid ensures that medical devices are packaged efficiently and safely, meeting the stringent requirements of the industry.

Diverse Packaging Formats

Ossid’s medical form fill seal machines are not limited to a single packaging format. They offer an array of packaging options to suit different products and applications. These include ambient packaging, modified atmosphere packaging (MAP), vacuum packaging, and vacuum skin pack (VSP) formats. The flexibility to run both flexible and rigid films further enhances their versatility.

High Speeds and Large Capacity

In the medical device industry, time is of the essence. Ossid’s medical machines boast impressive output rates of up to 30 cycles per minute. This high-speed capability ensures that large capacity requirements can be met efficiently, helping manufacturers meet demand without compromising quality.

Additional Features and Benefits

Ossid’s medical form fill seal machines come packed with additional features and benefits that enhance performance and ease of use. These include an auto web aligner, static eliminator, hinged upper tooling, and servo actuated presses. The machines also feature a robust framework and guarding package for added safety. Customers have the option to integrate vision systems, filling systems, reject systems, as well as printer and coding systems, making the packaging process seamless and efficient.

Clean Room Environments

The medical industry demands strict adherence to cleanliness and sterility. Ossid addresses this need by offering medical machines that can be built for clean room environments. This ensures that the packaging process maintains the highest level of hygiene and product integrity.

American Made, Precision Engineered

Ossid takes pride in its American-made medical form fill seal machines. Built with precision engineering and using high-quality materials, these machines stand the test of time and deliver consistent performance. The 8000 Series, in particular, offers stainless steel construction, Allen Bradley control systems, and SMC Pneumatics, ensuring durability and reliability in the long run.

Meeting Unique Medical Device Packaging Needs

Ossid’s 8000 Series thermoform fill and seal machines are specifically designed to cater to the diverse and specialized needs of the medical device industry. With the ability to produce a wide range of package types, from flexible packaging to foil-foil packaging and more, Ossid’s machines are adaptable to various medical products.

In conclusion, Ossid’s expertise within the medical device industry is second to none. Their medical horizontal thermoform fill seal machines offer customization, high speeds, and versatility in packaging formats, making them ideal for meeting the unique needs of medical device manufacturers. With their commitment to precision engineering, safety, and customer satisfaction, Ossid continues to be a reliable partner for those seeking efficient and innovative medical device packaging solutions.

Subscribe to our email list for the latest in flexible packaging news.

Ossid provides superior tray overwrapping, flow wrapping, weigh price labeling, case scales, and horizontal thermoform fill & seal machinery. We are committed to designing and building solutions that protect product quality and fully meet our customers’ production needs.