In order to guarantee a hermetic seal, you need time, temperature and pressure.

Written in Collaboration with Jared Rangel, Owner of Left Coast Packaging Solutions

Jared is also the sales contact for Ossid opportunities in California, Nevada, and Arizona.

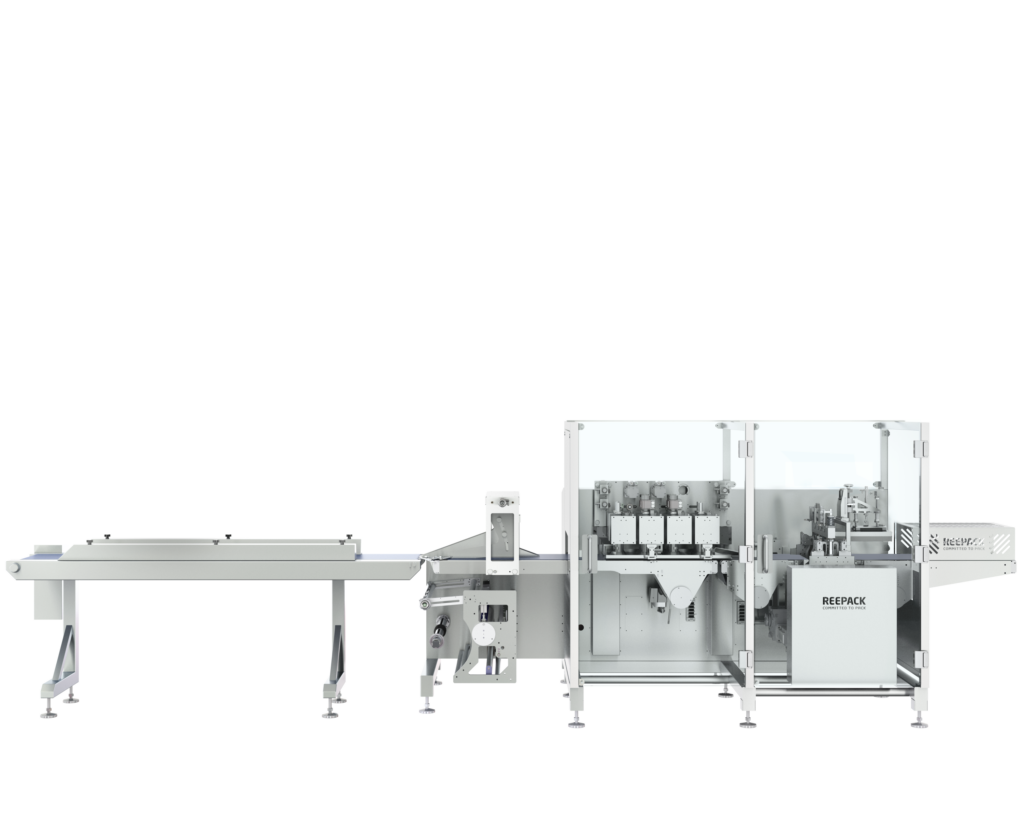

Rotary Motion Flow Wrapper: Reepack ReeFlow 50

On a rotary jaw machine, the point-to-point contact time is minimal, so if you slow down the jaw speed, increase the temperature and tighten the pressure on the jaws, and have good film… there is a chance that it can be hermetically sealed, but it cannot be guaranteed.

In order to have a guaranteed hermetic seal, Reepack offers two types of sealing technology that can do this.

Long-Dwell Flow Wrapper: Reepack ReeFlow 200

This jaw-type is recommended if a hermetic seal is required for the product application.

A long dwell sealing head follows an oval cam and gives even more point-to-point travel and can increase pressure by changing out the springs on the jaws. A single servo drives the head around the cam. This application is used in bakery, ready-to-eat, produce and wet wipe industries. With a long dwell head, you can run thicker film that has a higher oxygen barrier. Typical speeds for something like this can range from 15ppm – 120ppm.

Box Motion Flow Wrapper: Reepack ReeFlow 300

Rather than following a cam, a box motion uses two servos to open and close the jaws and move them from point A to point B. This jaw gives you the most point to point contact and also the most pressure on the jaws. This head is used heavily in the meat and cheese industries when film will have a vacuum drawn on it. Because the jaws can also open wider, it lends itself to larger products. Because of the inertia of the mass of the jaw moving left to right, this is typically a slower speed machine running up to 60ppm.

Modified Atmosphere Packaging (MAP) Process

When thinking about doing MAP on your product a lot of people will suggest throwing a gas lance on the machine and nitrogen in the bag and call it a day. There is a lot more thought that needs to go into the process.

Below are some questions to consider:

- For the hermetic seal, what is my goal in Hg and for how long?

- What gas mixture should I use?

- We suggest using a food science lab to look at the ingredients and provide a report of exactly what you need

- What should my residual oxygen in the package be at time of packaging?

- What should my residual oxygen be after packaging?

- If you’re dealing with porous bread, the product will de-gas after it’s been in the package so if you have 3% at time of packaging, once it degasses it might be at 18%. There are solutions to lower this, we just need to know the goal so we can assist.

- Are you trying to extend the shelf life or stop staling?

- From our experience, MAP does not stop staling.

Ossid is the North American master distributor of the Italian-based Reepack brand, providing all sales and support, including parts, service, and training.

Reepack has four flow wrapper styles to better satisfy the needs of customers based on their specific applications.

Subscribe to our email list for the latest in flexible packaging news.

Ossid provides superior tray overwrapping, flow wrapping, weigh price labeling, case scales, and horizontal thermoform fill & seal machinery. We are committed to designing and building solutions that protect product quality and fully meet our customers’ production needs.